Description

Challenges with Traditional Machine Inspection Tools

- Inaccurate Measurements : Traditional portable measurement tools often provide unreliable results, leading to incorrect predictions of machine malfunctions and ineffective predictive maintenance.

- Undetected Anomalies: Traditional systems may miss certain machine anomalies. In contrast, smart sensors paired with AI technology can identify issues more quickly and accurately.

- High Inspection and Maintenance Costs: Regular manual inspections are labor-intensive and costly. Transitioning to smart sensor and predictive maintenance can significantly lower these expenses.

- Safety and Environmental Risks: Working near live machinery poses substantial risks of accidents and environmental harm. Adopting smart factory solutions can effectively mitigate these dangers.

REPCO NEX Vibrationostic System (RVS)

Wireless machine condition monitoring system designed to overcome these challenges by enhancing the efficiency of machine inspection and maintenance, reducing costs, and improving workplace safety in smart manufacturing. By integrating sensors with AI, this system ensures maximum effectiveness in monitoring.

Easy and Quick Installation

To view an example installation click here >> https://youtu.be/49m5xzo3elQ

admin –

Feature Highlights of the REPCO NEX Vibrationostic System (RVS)

• Real-Time Machine Health Monitoring: Sensors continuously measure machine vibrations within IoT networks, allowing for early detection of any abnormalities.

• Advance Abnormality Warning: When an abnormality is detected, the system immediately sends a warning signal to users, providing at least three months of lead time for effective preventive maintenance planning.

• User-Friendly Interface: Results are displayed via a dashboard on mobile devices and tablets, offering an intuitive and visually appealing interface for easy and quick monitoring and management within the smart factory.

• AI-Powered Data Analysis: The system accurately identifies the type of damage, reducing both the cost and time required for on-the-spot repairs.

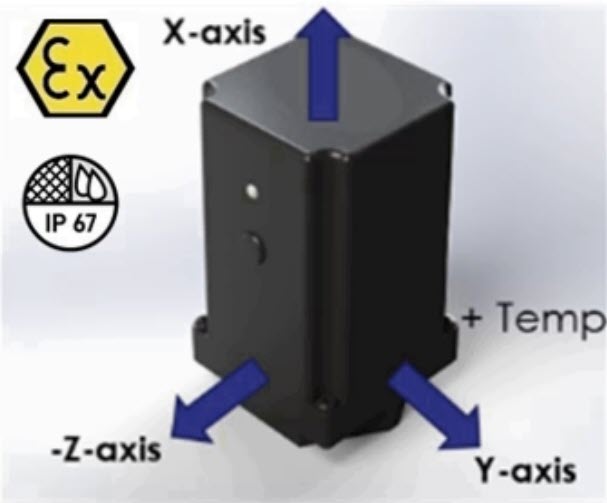

• 3-Axis Vibration Sensor: Capable of measuring vibrations across all dimensions, this sensor enhances the accuracy of abnormality detection.

• ZETA Technology: This unique technology expands the signal reception area, allowing sensors to be installed in hard-to-reach locations within the smart factory and covering more machines.

• Long-Lasting Battery: With a battery life of 2 years (depending on usage), the system minimizes the frequency of battery replacements, lowering maintenance costs.

• IP67 Waterproof and Dustproof Rating: The sensor is designed to operate in a variety of environments, including harsh weather conditions and dusty areas.

• Safe for Hazardous Areas: The sensor is engineered for safe use in hazardous environments.

• Comprehensive Monitoring: The system monitors 120 types of machines and detects 20 types of anomalies in smart manufacturing settings.