Click to See Videos

Transform your factory into a smart industry

Digital transformation: Smart manufacturing

Challenges with Traditional Machine Inspection Tools

Inaccurate Measurements : Traditional portable measurement tools often provide unreliable results, leading to incorrect predictions of machine malfunctions and ineffective predictive maintenance.

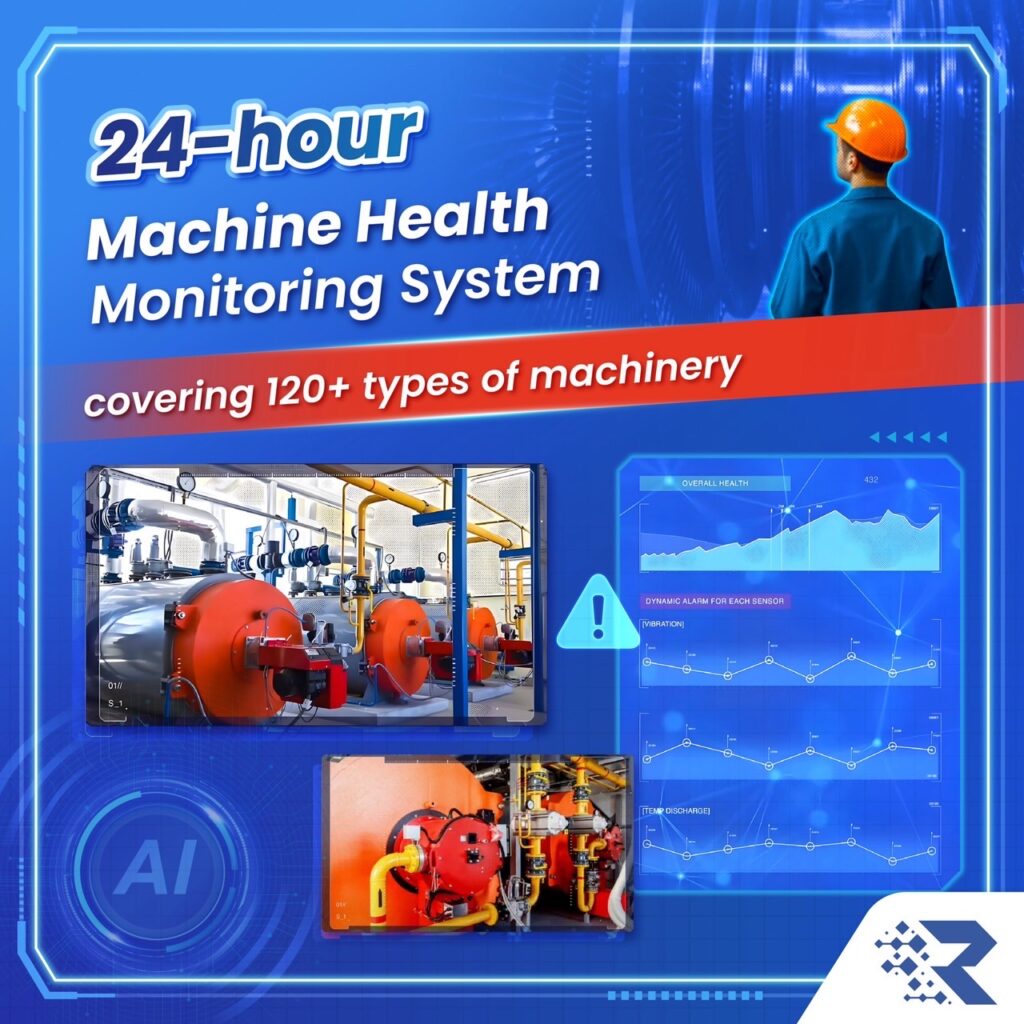

Undetected Anomalies :Traditional systems may miss certain machine anomaliesIn contrast, smart sensors paired with AI technology can identifyissues more quickly and accurately.

High Inspection and Maintenance Costs : Regular manual inspections are labor-intensive and costly. Transitioning to smart sensor and predictive maintenance can significantly lower these expenses.

Safety and Environmental Risks : Working near live machinery poses substantial risks of accidents and environmental harm. Adopting smart factory solutions can effectively mitigate these dangers.

How Our Services Enhance Business Efficiency and Profitability?

Improve Safety : Reduce the risks associated with inspecting machinery in hazardous or inaccessible areasby utilizing IoT technology and automation systems, such as smart sensors and smart motors, to conduct inspectionsinstead of exposing personnel to danger.

Reduce Costs : Prevent machine failures with predictive maintenance systemsthat lower repair costs and downtime while extending machine lifespan by 30-50%,ultimately reducing overall expenses.

Minimize Labor Requirements : Smart manufacturing decreases the need for manual inspections, cutting personnel costs and allowing

resources to be allocated to higher-value tasks.

Save Time :Automated fault diagnosis systems detect problems more swiftly enabling timely resolutions.This reduces the risk of emergency downtime by 50-90% ensuring smooth businessoperations.